Digital Tobacco and R&D of New Tobacco-Processing Technologies

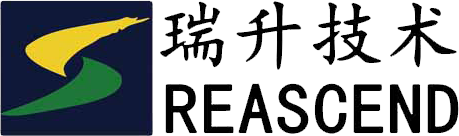

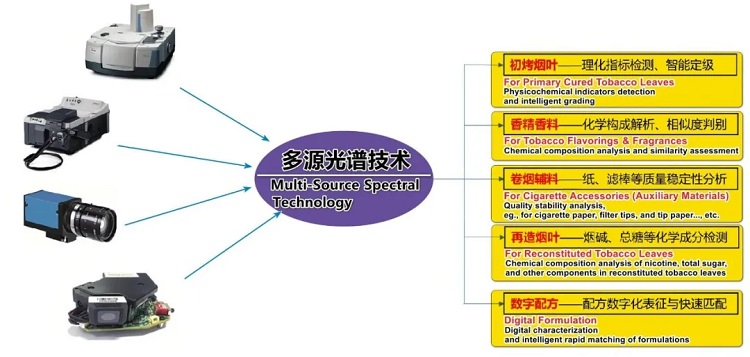

1. Multi-Source Spectral Technology

By organically integrating spectral technologies such as ultraviolet (UV), visible light, near-infrared (NIR), mid-infrared (MIR), and hyperspectral imaging, Yunnan Reascend Tobacco Technology (YRTT) has developed a technological system based on multi-source spectral analysis for quality control of tobacco raw and auxiliary materials—including tobacco leaves, flavorings and fragrances, cigarette accessories, and reconstituted tobacco leaves (RTL). Applying this technological system enables the achievement of the following specific objectives:

For Primary Cured Tobacco Leaves—Physicochemical Analysis and Intelligent Grading:

Rapid and non-destructive detection of key physicochemical indicators—such as total sugar, total nitrogen, nicotine, and moisture in tobacco leaves—is enabled. Combined with image recognition technology, it supports the development of discriminant models for leaf grade, maturity, and uniformity, establishing a fully digitalized quality management system for tobacco raw materials.

For Flavorings & Fragrances—Chemical Composition Analysis & Similarity Assessment:

By applying spectral technology to resolve the microscopic chemical composition of flavor ingredients, a characteristic fingerprint library for natural and synthetic flavorings is established. Thus, precise similarity discrimination is enabled through comparison of odor-active substances, supporting flavor blending and traceability.

For Cigarette Accessories (Auxiliary Materials)—Quality Stability Analysis of Cigarette Paper, Filter Rods, etc.:

Specialized rapid-testing devices have been developed to dynamically monitor critical indicators such as the triacetin content in filter rods and the quality stability of cigarette paper, enabling quick assessment of quality fluctuations during the production of cigarette accessories (auxiliary materials).

For Reconstituted Tobacco Leaves (RTL)—Detection of Chemical Components such as Nicotine and Total Sugar:

A comprehensive quality monitoring system has been established across the entire RTL production process, enabling real-time monitoring of gradient distributions of chemical components such as nicotine and total sugar in raw materials, coating solutions, and finished products, effectively supporting comprehensive quality improvement of RTL product.

Digital Formulation—Digital Characterization and Rapid Matching of Formulations:

A digital characterization database for tobacco materials has been built. Integrated with near-infrared (NIR) rapid screening and chemometric algorithms, it achieves intelligent matching and dynamic optimization of formulation components, and supports rapid iteration and standardized output in formulation design.

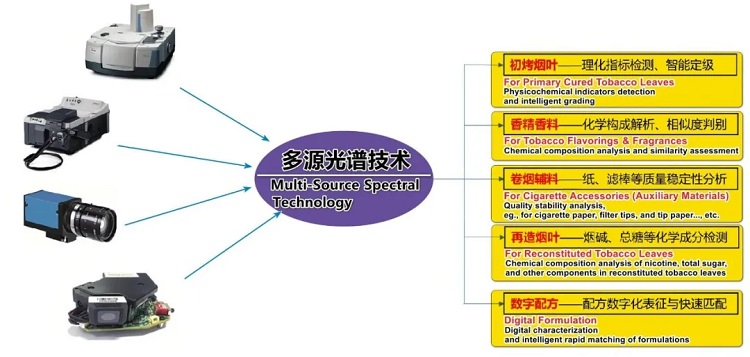

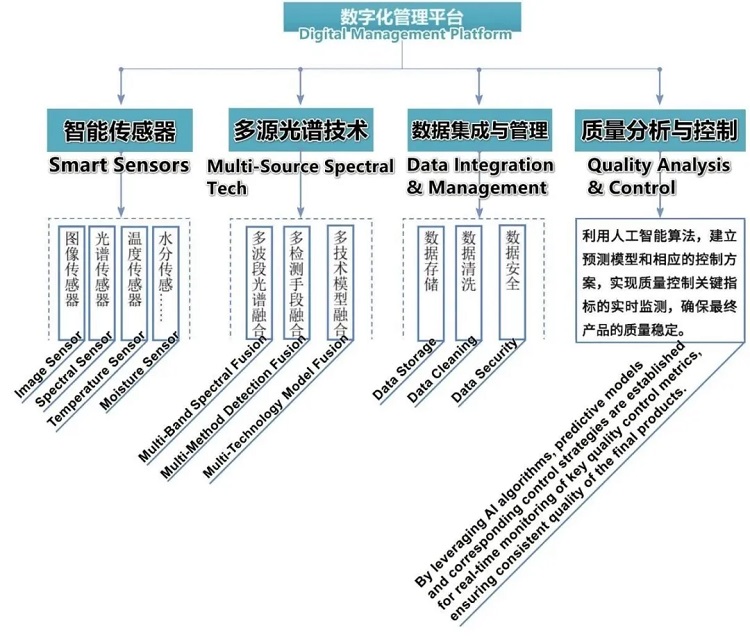

2. Digital Management Platform

By deploying spectroscopic and other intelligent sensors at key nodes throughout the production process for data collection, we have established a robust data acquisition system and a unified digital management platform. This platform integrates intelligent equipment, data acquisition & analysis systems, advanced algorithms, and predictive models, achieving a digital control architecture that spans the entire production process.

The platform monitors and collects relevant quality indicators within and between production batches, and by leveraging edge computing devices incorporating AI algorithms, compares real-time calculation results against anomaly detection models, enabling quality control that is visible, assessable, actionable, and traceable.

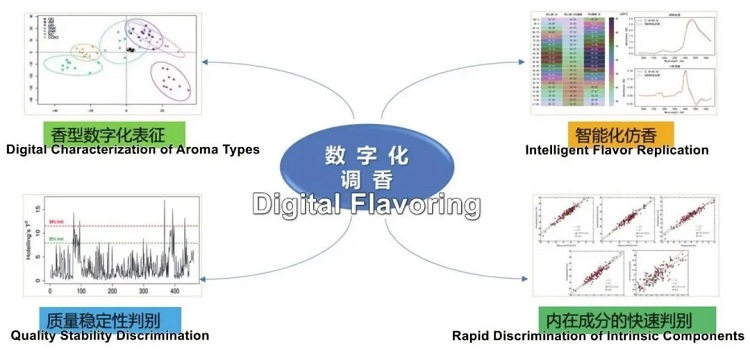

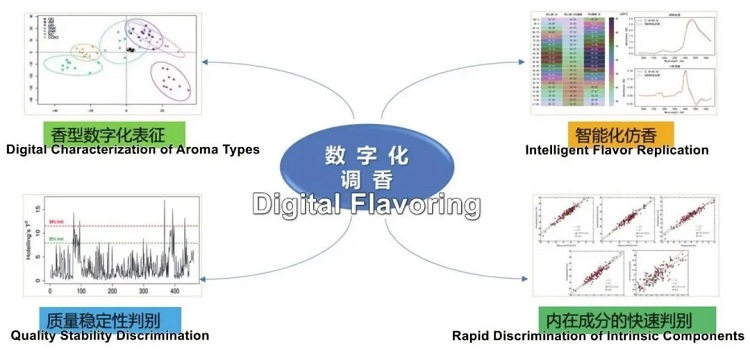

3. Digital Flavoring Technology

By researching the digital characterization of characteristic information of tobacco flavor ingredients and using gas chromatography–mass spectrometry (GC-MS) to establish fingerprint spectra of aroma components, we have created a digital characteristic library containing vast amounts of aroma substances.

Additionally, we have developed an intelligent flavoring algorithm platform powered by machine learning, which can automatically identify key characteristic components of target aroma and generate optimized ingredient ratio schemes. In practical applications, the platform enables:

Virtual Screening of Flavor Ingredients: Predicting aroma thresholds and stability of compounds through molecular simulation technology.

Dynamic Formulation Optimization: Adjusting flavoring strategies in real-time based on sensory evaluation data.

Quality Prediction Modeling: Establishing correlation models between smoke components and sensory characteristics, significantly improving the reliability of prediction.

Thus, a comprehensive, multi-dimensional intelligent system for aroma identification, replication, and creation has been established. This system organically integrates digital flavoring technology with leaf group formulations, cigarette auxiliary materials, and quality control, significantly shortening the R&D cycle for new products, achieving internationally leading consistency control in formulations, and advancing flavoring technology from experience-driven to data-driven leapfrog development.